Companywise Plant List

Bihar Cement Plant (A unit of Shree Cement Ltd.), Aurangabad BIHAR 3. New Bihar Cement Plant (A unit of Shree Cement Ltd.), Aurangabad BIHAR 4. Odisha Cement Plant (A Unit of Shree Cement

WhatsApp)

WhatsApp)

Bihar Cement Plant (A unit of Shree Cement Ltd.), Aurangabad BIHAR 3. New Bihar Cement Plant (A unit of Shree Cement Ltd.), Aurangabad BIHAR 4. Odisha Cement Plant (A Unit of Shree Cement

Among the different varieties of cement, India produces Ordinary Portland Cement (OPC), Portland Pozzolana Cement (PPC), Portland Blast Furnace Slag Cement (PBFS), Oil Well Cement, Rapid Hardening Portland Cement and Sulphate Resisting Portland Cement. The share of blended cement in total cement production

UltraTech Cement Limited is an Indian cement company based in is a subsidiary of the Indian multinational conglomerate, Aditya Birla Group.. Ultratech is the largest manufacturer of grey cement, ready mix concrete (RMC) and white cement in India with an installed capacity of million tonnes per annum, and is the only company in the world to have a capacity of over 100 million

#0183;#32;Type of Process. There are mainly two types of Cement Manufacturing process: Wet Process; Dry Process Wet Process; Under wet process type, the raw materials are mixed with water so as to ensure better homogenization which leads to better quality of clinker. In the whole process, moisture content in the slurry is 3550%.

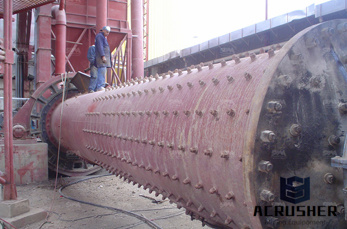

The kiln has to operate continuously in order to ensure a steady regime, and therefore uniformity of clinker. The larger existing kiln in a wet process plant produces 3600 tonnes of clinker per day. The manufacture of cement by wet process is energy intensive and thus uneconomical as compared to dry process and semi dry process.

For details about Basic Process of Cement Manufacturing, refer toCement Manufacturing Process

Sep 17, 2017#0183;#32;It is the secondbest cement brand, founded in 1979 (Bewar in the Ajmer district of Rajasthan), with the production capacity of Million Tonnes Per Annum (MTA).It has a total of 8 cement manufacturing plants and more than 5411 employees in its abode. The headquarter is in Kolkata, India, while the Ramp;D centre is located in Bewar and Ras, Uttar Pradesh.

Similarly slag is a byproduct of Steel making process and is often sold to cement makers as a substitute for limestone in the cement making process. Cement manufacturers often try to keep their plant near to a power plant, because neither slag nor flyash can be transported across long distance.

Crushing. Raw Mill. Cooler. Preheater and Kiln. Blending and Storage Silo. Clinker storage. Grinding. Packing. For details about Basic Process of Cement Manufacturing, refer

Before starting to build a cement plant, it is imperative to know what the cement making process involves. The cement manufacturing process starts with mining of limestone followed by grinding it with other raw materials like clay, shale, bauxite, iron ore, etc. to prepare a raw meal, which is heated at a sintering temperature of 1,400 to 1,500 degree Celsius in a kiln to manufacture clinker.

Cement Manufacturing Process. The cement manufacturing process starts with the mining of limestone that is excavated from open cast mines. Then this limestone is crushed to 80 mm size and is loaded in longitudinal stockpiles. Limestone is taken out diagonally from these stockpiles for grinding in raw mill hoppers. As mentioned earlier coal is used as a fuel to heat the raw materials in the cement

Cement Plant Location Information for India. Cement plant locations and information on India can be found below. For full access to the database, purchase The Global Cement Report, 13th Edition.

Apply To 11089 Cement Plant Jobs In India On, India''s Job Portal. Explore Cement Plant Job Openings In India Now!

Aug 30, 2012#0183;#32;Generally cement plants are fixed where the quarry of limestone is near bye. This saves the extra fuel cost and makes cement somehow economical. Raw materials are extracted from the quarry and by means of conveyor belt material is transported to the cement plant. There are also various other raw materials used for cement manufacturing.

Nuvoco Vistas Corp. Ltd. has been a part of the Indian construction landscape since 1999; through its cement business. We currently have six cement and close to sixty five ready mix concrete plants in India. We have an established presence across all major cities and towns in India. Our operations across two business divisions Read More

#0183;#32;The cement manufacturing process involves several key steps, including preparing the raw materials, grinding the materials together, heating the newly formed clinker in a kiln, and finishing the cement with fine of the main ingredients used to make cement include limestone, clay, shale, iron, and manufacturing techniques will use either wet or dry grinding, but

The cement manufacturing process starts with mining of limestone followed by grinding it with other raw materials like clay, shale, bauxite, iron ore, etc. to prepare a raw meal, which is heated at a sintering temperature of 1,400 to 1,500 degree Celsius in a kiln to manufacture clinker.

Awarpur Cement Project, Taluka: Korpana, District: Chandrapur, Marashtra 442 917. (07173) 266323 (07173) 266339

The grinding plant at a cement factory is used to reduce the particle size distribution of various materials such as raw meal, fuel or clinker to set parameters. In a sense, a grinding plant uses energy (through milling) to create fineness and it is the production personnel''s aim

Two main methods of cement manufacturing were prominent, the dry process and wet process. Dry process now has almost replaced the wet process since wet process consumes high thermal energy for

Jul 01, 2020#0183;#32;The study thus analyzes a coprocessing trial of a month in a cement plant in the southern part of India and based on the obtained data, the environmental and operational sustainability was studied. The economic benefit obtainable was also analyzed based on the achieved substitution benefit.

Indian cement plants are comparable with the best in the world in respect of production facilities, technology, energy efficiency Indian Process Control DDC Fuzzy Logic expert system 6 . Achievements of Indian Cement Industry 7 . Sustainable and Green Production

Indias Star Cement has announced an (US61m) investment in Bengal through the construction of its new 2Mta grinding unit. It will be the companys first facility in the state and the government has already cleared land for the project in Jalpaiguri, according to the Times of India.

#0183;#32;All the L amp; T Cement plants have high quality laboratories and testing units where the cement producing process goes through rigorous examination and quality control techniques. Through the testing process, it is ensured that the clinker and the cement that is produced are of the best quality according to the international standards.

WhatsApp)

WhatsApp)