(PDF) SAG mill circuit optimisation at Ernest Henry

SAG milling in closed circuit with a vibrating screen followed by a ball mill . than the cause, by beefing up the liner portion of the lifter as can be . seen in Figure 5.

WhatsApp)

WhatsApp)

SAG milling in closed circuit with a vibrating screen followed by a ball mill . than the cause, by beefing up the liner portion of the lifter as can be . seen in Figure 5.

To participate in the 911Metallurgist Forums, be sure to JOIN amp; LOGIN Use Add New Topic to ask a New Question/Discussion about Grinding. OR Select a Topic that Interests you. Use Add Reply = to Reply/Participate in a Topic/Discussion (most frequent). Using Add Reply allows you to Attach Images or PDF files and provide a more complete input. Use Add Comment = to comment on someone elses

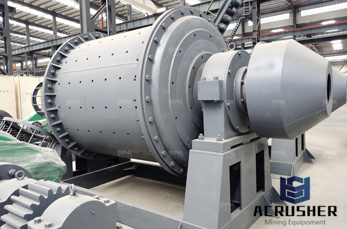

The ball charge of a SAG mill is about 29% to 30%. By friction and influence of tumbling balls inside rotating cylinder grinds the raw material to the required fineness. The internal machinery of ball mill grinds the raw material into the powderlike material, And if extreme fineness and refinery are required then rotation go on continue.

#0183;#32;There appears to be a lot of factors influencing milling machine table droop. I imagine years of unsupported center of a relatively thin iron casting, metallurgical problems of which I''m only vaguely aware, and the comprssive stresses from years of T slot peening and table load as gbent suggests are the principle causes.

The paper is illustrated by trend plots taken from a SAG mill in a major gold mine. The paper goes on to explain the practical causes of the instability ranging from inappropriate type 2 control strategies to poor control loop tuning and to inappropriate operator intervention caused by lack of operator training.

Apr 21, 2014#183; The heat causes the carbide binder, or cobalt, in the insert to soften. Mechanical loading happens when the pressure of the insert against the workpiece makes the insert deform or sag at the tip, eventually breaking it off or leading to rapid flank wear.

Generally, the discharge from AG/SAG mills consists of one or both of the following components: slurry (water and finer particles) and pebbles (20100 mm). Single stage AG/SAG mills have to handle large amounts of slurry as they are generally in closed circuit with classifiers whose circulating loads reach as high as 400500%.

causes of ins ility in sag milling SAG Mill Control Instability: Causes and Solutions CEEC SAG Mill Control Instability: Causes and Solutions Oscillatory unstable behaviour in a SAG mill is characterised by the mill constantly cycling between an overload condition and recovery from that condition by a substantial reduction in feed rate tonnes.

Autogenous or autogenic mills are socalled due to the selfgrinding of the ore: a rotating drum throws larger rocks of ore in a cascading motion which causes impact breakage of larger rocks and compressive grinding of finer particles. It is similar in operation to a SAG mill

Difference Between Sag Mill vs Ball Mill mech4study

SAG Mill Control Instability: Causes and Solutions | CEEC The . Oscillatory unstable behaviour in a SAG mill is characterised by the mill constantly cycling between an overload condition and recovery from that condition by a #187; Free online chat! Mill (grinding) Wikipedia, the free encyclopedia. A SAG mill with a diameter 44 in diameter has been designed with a power

Only about % of impacts can cause i mpact breakage, and a bout 2% of impacts require . known in the industry, represent ing a significant increase in OPEX over sim ple SAG milling. However,

LG A mill power equation for SAG mills. Minerals and Metallurgical Processing. Feb 1990 pp5762. Gross power No load power Net power drawn by the charge () The net power is calculated from Net power e! c./ Watts () In equation, D is the diameter inside the mill liners and Le is the effective length of the mill including the

#0183;#32;Based on a discrete representation of the impactlike cutting process combined with the exact analytical solution of the free tool vibration, a timedomain analytical method for stability prediction was developed which revealed that there exist two types of instability in milling: the Hopf bifurcation, which causes the quasiperiodic chatter, and the period doubling or flip bifurcation, which

The heat causes the carbide binder, or cobalt, in the insert to soften. Mechanical loading happens when the pressure of the insert against the workpiece makes the insert deform or sag at the tip, eventually breaking it off or leading to rapid flank wear.

AG and SAG mills are now the primary unit operation for the majority of large grinding circuits, and form the basis for a variety of circuit configurations. SAG circuits are common in the industry based on: High singleline capacities (leading to capital efficiency) The ability to mill a broad range of ore types in various circuit configurations, with reduced numbers of unit operations (and a

WhatsApp)

WhatsApp)