Dense medium separation (DMS) | Request PDF

This chapter presents the dense medium separation, which is applied to the preconcentration of minerals that is the rejection of gangue prior to grinding for final liberation.

WhatsApp)

WhatsApp)

This chapter presents the dense medium separation, which is applied to the preconcentration of minerals that is the rejection of gangue prior to grinding for final liberation.

Dense media separation is a wellestablished density separation process, ideally suited for the separation of minerals, ores and metals. Applications: As Heavy Media in the Dense Media Separation process of Mining and Metal Recovery .

Dense Media Separation Process Chemicals. FOB Reference Price: Get Latest Price Chromite ore dense media media separation plant for chrome ore, apr 02, 2013 preconcentration of base metal ores by dense medium separation, performance of the plant without having to pursue costly pilot plant testwork target discards, dense medium separation dms is a mature, 50 year old

#0183;#32;Introduction Dense medium separation (or heavy medium separation (HMS), or the sinkandfloat process) is applied to the preconcentration of minerals, i. Learn more about Chapter 11: Dense Medium Separation (DMS) on GlobalSpec.

The Dense Media Separation process consist of both the separation and medium recovery circuits. The ferrosilicon properties are designed to maximize separation efficiency while optimizing medium recovery. Dense medium beneficiation is a well established process in the

Dense Media Separation (DMS), a PreConcentration Method The Halyard team offers proven expertise in the design, engineering and operations of preconcentration methods, Dense Media Separation (DMS) (best known for the recovery of diamonds and the cleaning of coal streams). You can count on Halyards specialist knowledge in numerous of preconcentration methods, plus the expertise for []

Dense Media Separation is a wellestablished separation process used in the extraction or processing of diamonds from waste material, and is widely used in the diamond processing and other mineral processing industries. For this purpose, DMS Powders produces the ferrosilicon powders, which is used in the Dense Media Separation in diamond processing.

HMS and DMS are acronyms for Heavy (Dense) Medium Separation and is applied to the process of preconcentration of minerals mainly the production of a high weight, low assay product, which may be rejected as waste. In principle it is the simplest of all gravity processes and is a standard laboratory method for separating minerals of different specific gravity. Fluids of suitable density

14 SEPARATION TECHNIQUES Introduction The methods for separating, collecting, and detecting radionuclides are similar to ordinary analytical procedures and employ many of the chemical and physical principles that apply to their nonradioactive isotopes. However, some important aspects of the behavior of radionuclides are

Heavy media or dense media separation (these include the Sepro Condor DMS, baths, drums, larcodems, This chemical binds to the surface of the particles as it is a surfactant. Magnetic separation is a process in which magnetically susceptible

Dense medium separation (or heavy medium separation (HMS), or the sinkandfloat process) is applied to the preconcentration of minerals, the rejection of gangue prior to grinding for final liberation. It is also used in coal preparation to produce a commercially graded endproduct, clean coal

Jul 03, 2019#0183;#32;Dense media separation (DMS for short) is a widely used in the mining industry by densitometry errand valuable minerals and nonvaluable rock separation process. The process can be conducted at particle sizes as coarse as 300 mm and as fine as 500 m with high separation efficiency, depending on the liberation characteristics of the valuable

#0183;#32;Currently, the most commonly used materials for creating dense medium slurries are ferrosilicon and magnetite. Both materials can produce suspensions that can be used in DMS and efficiently have the benefit of being easily recoverable by magnetic separation. Ferrosilicon has a higher specific density ( g/cm. 3.

through Dense Medium Separation (DMS). Recently, MetSolve Laboratories, in conjunction with Sepro Mineral Systems, has conducted a number of pilot scale test programs utilizing the Condor centrifugal, multistage, dense media separation system. The mechanical design, operational advantages and findings from pilot plant tests and heavy

May 06, 2015#0183;#32;DMS Powders business started as part of Amcor in 1949 with the production of Milled Ferrosilicon (FeSi) for use in Dense Medium Separation in the extraction of diamonds. In the 1950s the production facilities were relocated to the current site near Meyerton. Atomised production commenced in

Dense Medium Separation (also called Heavy Media Separation) is a wellestablished density separation process. Dense Medium Separation (DMS) uses the characteristic differences in density of the input material to enact a gravimetricbased separation. Due to the robustness of the process, DMS can be used in the separation of minerals, ore bodies and

In a Dense Media Separation (DMS)/ Heavy Media Separation( HMS) plant, powdered ferrosilicon (an alloy of iron and silicone) is suspended in water to form a fluid near the density of diamond ( g/cm3), to which the diamondbearing material is added to begin the separation process of the heavier minerals from the lighter material.

Multotec dense medium cyclones are field tested to improve separation accuracy and efficiency. The engineered tile wear surface Each engineered tile is specifically designed for its position in the complete tile kit, ensuring a very tight fit, with the absolute minimum space at the end of the tile joints.

gangue in order to separate these materials. Dense Medium Separation (DMS) cyclones form part of this dense medium beneficiation process and, as the name indicates, makes use of a medium (a suspension of magnetite in water) in conjunction with the forces acting within such a cyclone to efficiently clean the coal that is being treated.

Plant operating efficiency monitored using density tracers; In certain circumstances, dense media separation plants can be configured to follow complex gravity circuits, multi gravity separation and/or other separation techniques such as flotation. This can provide effective low cost solutions to allow the optimal economic recovery of complex ores.

2 1a) Densemedium baths (Osborne 1988). Dense medium baths are simply large tanks/vessels filled up with a dense medium, usually a fine magnetite suspension in water. The feed to the bath usually a deslimed coarse coal is dumped onto the surface of the medium and spontaneous separation is allowed to take place. There are two main types of densemedium baths: deep baths and shallow baths.

A separation process is a method that converts a mixture or solution of chemical substances into two or more distinct product mixtures. At least one of results of the separation is enriched in one or more of the source mixture''s constituents. In some cases, a separation may

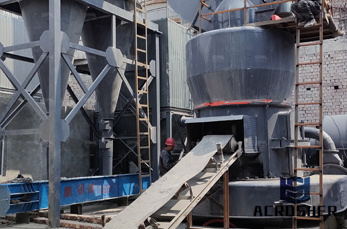

DENSE MEDIA SEPARATION (DMS) PLANTS. The DMS process is employed for the preconcentration of suitable ores upstream from expensive downstream metallurgical processes, and also employs the separation of heavy waste particles (such as metals) from light waste particles. Process description DMS cyclone plants.

Separation in dense media uses a liquid medium in which the components to be separated are immersed. This medium can be water, an organic liquid (exclusively in laboratory), brines (calcium chloride or zinc type salts) or a clay, sand, magnetite or ferrosilicon based suspension, where the suspension behaves as a pseudofluid.

WhatsApp)

WhatsApp)