How Does The Process Of Deep Shaft Mining Work

What process is used for surface mining What mining process in which rock is stripped away to expose Deep shaft mining, Mygrandfather worked in a plant that did the refining end of this work

WhatsApp)

WhatsApp)

What process is used for surface mining What mining process in which rock is stripped away to expose Deep shaft mining, Mygrandfather worked in a plant that did the refining end of this work

Shaft sinking being a costly process, nature of strata through which shaft has to be sunk should be ascertained by a proving bore hole near the proposed shaft site. Trial pits 3 m to 5 deep, are sunk to test bearing pressure of the soil for structures associated with winding and other heavy installations.

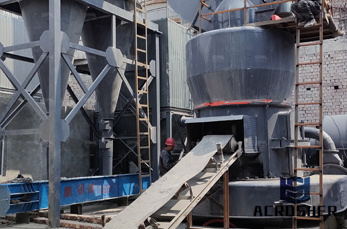

We go for deep shaft mining when the deposit lies at a greater depth or when mining through opencast method has reached the economical pit limit it is no longer profitable to mine through open cast system. A few disadvantages of deep shaft sy...

#0183;#32;Ever wonder how people mined for gold? Have no fear! You can use a pan, a large drill, and even explosives! Anthony did some digging and found out many of th...

It is necessary to take into consideration the capability of the mine shaft to penetrate deep into underground mining. The process by which the horizontal working off the shaft is referred to as drifts, galleries or levels. It spreads from the central shaft towards the

Deep Shaft Mining is two tunnels going deep underground, on tunnel for the miners to come up and down and the other for the coal to be lifted up to the ground.

The underground mining methods we use include room and pillar, narrow vein stoping and largescale mechanised mining. Room and pillar mining is a style of mining where tunnels are driven in a chess board pattern with massive square pillars between them which are gradually cut away as the work proceeds. We use this for mining coal.

The deep underground mine employs a sequential grid mining method. The shaftsinking process at Mponeng began in 1981 while gold plant complex and the shafts were commissioned in 1986. The mine is undergoing a twophase expansion, which will extend its mine life upon completion.

The Mponeng gold mine was originally known as the Western Deep Levels South Shaft or the No. 1 Shaft. The underground mine comprises a twinshaft system housing two surface shafts and two subshafts. After mining, The Mponeng gold plant has the capacity to process 160,000 tonnes of ore a

how does the process of deep shaft mining work; Salt Production and Processing Morton Salt. Salt Production and Processing Most mine shafts are lined with a concrete wall called a shaft liner After the work shift . disadvantages of deep mining BINQ Mining. May 02 2013

#0183;#32;Shaft miningalso referred to as shaft sinkingis a type of mining process used to vertically gain access to an underground mining facility. There are many different components which make up the shaft, all of which play a very important role in the mining process.

The underground mining methods we use include room and pillar, narrow vein stoping and largescale mechanised mining. Room and pillar mining is a style of mining where tunnels are driven in a chess board pattern with massive square pillars between them which are gradually cut away as the work proceeds. We use this for mining coal.

#0183;#32;Shaft mining or shaft sinking is excavating a vertical or nearvertical tunnel from the top down, where there is initially no access to the bottom. Shallow shafts, typically sunk for civil...

In the case of artisanal mining, the extraction process usually takes a longer time as it involves low tech equipment and manual labor. Compared to alluvial mining, the postprocessing is shorter and is a less resourceconsuming task as diamonds are identified in situ of the work area.

shaft lining. Failure of deep closure structure: Galleries or mine works with connecting shafts may have been closed before the shaft was backfilled in order to avoid spreading of the backfilling material in the galleries. Structures generally consist of walls in hollow blocks, metal dams or concrete plugs.

Mining Mining Underground mining: When any ore body lies a considerable distance below the surface, the amount of waste that has to be removed in order to uncover the ore through surface mining becomes prohibitive, and underground techniques must be considered. Counting against underground mining are the costs, which, for each ton of material mined, are much higher underground than on the

Slope Mining With fast progress of modern industry, the demand for products manufactured from metal ores has gone up literally. In order to meet this demand, the awareness of uninterrupted mining, which can sharply elevate stope productivity and cut mining costs, has become a big trend in the development of mining techniques in underground mines.

WhatsApp)

WhatsApp)