(PDF) SIZE REDUCTION BY GRINDING METHODS

Milling is one of the The objective of this lesson is to provide the details of size reduction methods involved in mineral processing using grinding ball mills, grinding (steel)

WhatsApp)

WhatsApp)

Milling is one of the The objective of this lesson is to provide the details of size reduction methods involved in mineral processing using grinding ball mills, grinding (steel)

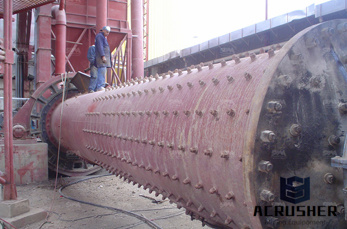

A ball mill, a type of grinder, is a cylindrical device used in grinding (or mixing) materials like ores, chemicals, ceramic raw materials and mills rotate around a horizontal axis, partially filled with the material to be ground plus the grinding medium. Different materials are used as media, including ceramic balls, flint pebbles, and stainless steel balls.

Crushing/grinding is typically the machining technique used in the first instance with freshly mined/quarried rocks, ores and minerals. Tolerant of large sized raw input materials, crushing can be thought of as a cruder technique than milling for example, as it produces comparatively larger sized output products; such as aggregates for construction and infrastructure building, small to

Grinding Grinding action Industrial grinding machines used in the mineral processing industries are mostly of the tumbling mill type. These mills exist in a variety of types rod, ball, pebble autogenous and semiautogenous. The grinding action is induced by relative motion between the particles of media the rods, balls or pebbles

#0183;#32;Ball milling and grinding media can also use hardened steel balls (shots, beads), which are available in different hardnesses in both highcarbon steel and chrome alloy steel. Linear ball mill grinding uses a linear model of balance and substitution for the real distribution for the time of grain processing inside the mill, which is a combination of ideal extrusion and ideal mixing.

A Ball mill of this size equipped with steel grinding media converts approx. 50 kW per m3 of feedstock. The feed product is fed continuously through the trunnion and is discharged through slots on the opposite side. The discharge rate can be adjusted as a function of the number of open slots.

We offer the complete range of mineral processing plants, mineral processing project and mineral grinding plant including ball mills for wet grinding, ball mills for dry grinding, wet scrubber, rod mills, vibratory screens, rotary type kilns, dynamic separators, rotary screens, mineral grinding plant, ball mills for wet grinding, ball mills for dry grinding, wet scrubber manufacturer

Milling is using carbide burs to cut into the block with a punching motion. A large carbide does the majority of the work, and then a finer finishing bur completes the details. There may be multiple sprue connections. It is currently limited to bi...

2 #0183;#32;Mineral processing, art of treating crude ores and mineral products in order to separate the valuable minerals from the waste rock, or gangue. It is the first process that most ores undergo after mining in order to provide a more concentrated material for the procedures of extractive metallurgy.

Grinding equipment has an impact on grinding cost and performance. Making a reasonable choice of grinding mill, reducing the grinding cost are an important way to improve your mineral processing

chrome steel balls grinding media for your ball mill in mongolia. We are one of the largest factory specialized in producing Forging Grinding Media Ball Rolling Grinding Media Ball and Casting Grinding Media Ball in China It was founded in 1988 located in Zhangqiu City Shandong Province China Annual Production Capacity is 50000 metric ton There are 120 employees covering an area of 15000

Milling Crushing typically takes RunofMine (ROM) ore down to particle sizes ranging from 6mm to 25mm, depending on the type of processes to follow. Crushed ore is fed into Mills in which the ore is mixed with water and may be ground down to a particle size, in the case of gold and copper, of about 75 microns ().

#0183;#32;In minerals processing most of the minerals are very place in a sequence of crushing and grinding (and/or milling). with either steel rods (rod mills) or balls (ball

Ball Milling is used in the processing of ceramics, paints, coal, pigments, feldspar, and more. In addition to grinding minerals down, a ball miller is often used to mix or blend materials. It can be used for wet or dry milling. Standard ball milling is performed by rotating the chamber around a horizontal axis.

Welcome to Taihong, the leading manufacturer of steel grinding media, just like high chrome grinding balls, forged grinding balls, grinding rods, cylpebs and ball mill wear parts. Established in 1981, to serve the cement, mineral processing, power plant, chemical and other industries more than 30 years.

Grinding Steel Ball For Mining Grinding Steel Ball For. Alibaba offers 12 654 grinding steel ball for mining products. About 32% of these are other fabrication services 22% are casting and 4% are bearing balls. A wide variety of grinding steel ball for mining options are available to you such as free samples paid samples. Get Price

WhatsApp)

WhatsApp)