Concentration Of Iron Ore With Magnetic Separation

concentration of ore by magnetic separation SBM Ball Mill. SBM is one of the biggest manufacturers in Aggregate Processing Machinery for the concentration of ore by magnetic separation

WhatsApp)

WhatsApp)

concentration of ore by magnetic separation SBM Ball Mill. SBM is one of the biggest manufacturers in Aggregate Processing Machinery for the concentration of ore by magnetic separation

Oct 01, 2012 #183; . html Iron ore beneficiation process flow for iron ore . magnetic separation . ball mill,iron ore concentration . Get Price And Support Online; Maximizing haematite recovery within a

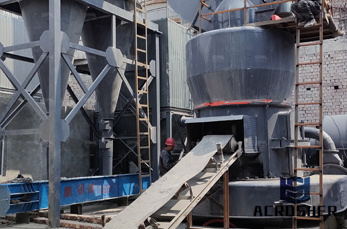

Magnetic Separation Process, Iron Ore Beneficiation Plant, Iron Ore Processing Plant. Magnetic separation process (iron ore beneficiation plant or iron ore processing plant) is made up of jaw crusher, ball mill, spiral classifier, magnetic separator, concentrator and dryer, etc.

Magnetic Seperation Of Iron From Its Ore. Concentration of iron ore with lowintensity magnetic separators has been used for decades in the recovery of magnetite while gravity separation and froth flotation are two important processes for mineral beneficiation other methods can be used to concentrate minerals and separate them from gangue and each other

Some harmful impurities overweight powdered iron, using new antiflotation process, but also part of the solution thoroughly powdered iron ore impurity content high. Zhengzhou Shanchuan Heavy Industry Co., Ltd., as a hightech heavy machinery manufacturer in Henan, has boasted with strong technical force and rich ore dressing experience, and

Dec 04, 2020#0183;#32;Methods such as screening, crushing, and grinding of iron ore are often used in various ways to purify it, along with several stages of magnetic separation. Raw iron ore has to be purified for use. The iron ore industry classifies the material by the concentration of the metal that is present after iron ore beneficiation has been completed.

Magnetic Iron Ore Separation Process Magnetic Iron Ore . Magnetic Separation and Iron Ore Beneficiation Magnetic separation is an old technique for the concentration of iron ores and for the removal of tramp iron Since 1849 a number of patents on magnetic separation have been issued in USA and texts of some of the patents before 1910 describe a variety of magnetic separators for

Table of ContentsMagnetic Iron Ore ResourcesHistory of Development of Magnetic Separator Treatment Method DeterminationPresent Practice and State of DevelopmentWet Magnetic Separation of Cornwall OreDustLow Grade of ConcentratesResults of Dry Separation in Testing LaboratoryNo. 234, Separation Test on Jackson Hill Ore, Arnold, N. In the West, capitalists have expended many millions

Iron Ore Magnetic Separator for iron ore concentration,US 3,200 33,000 / Piece, New, Magnetic Separator, Jiangxi, China (Mainland).Source from Jiangxi Shicheng Read more magnetic separation process of concentration of ore

After crushing, grinding, magnetic separation, gravity concentration etc, gradually we can get iron from natural minerals (iron ore). It is the mineral aggregates that contain iron or iron compounds which can be used economically.

Magnetic Separation Line Iron Ore Beneficiation Plant . Natural iron ore like magnetic iron ore or hematite iron ore can make ore beneficiation after series of measures The following is the process of ore separation 1Natural iron ore after coarse broken then it will be further broken by CrusherOr use onestage ball mill and twostage ball mill to make ore grinding.

Oct 04, 2018#0183;#32;Magnetic Separation and Iron Ore Beneficiation. Magnetic separation is an old technique for the concentration of iron ores and for the removal of tramp iron. Since 1849, a number of patents on magnetic separation have been issued in USA, and texts of some of the patents before 1910 describe a variety of magnetic separators for mineral processing.

Calcination of lowgrade laterite for concentration of Ni Concentration of Ni by magnetic separation Since the nickel in laterite is uniformly distributed and has a particle size of several nm (), the sample was first ground by using a laboratoryscale ball mill for 5 h (rotational speed of the

Iron magnetic seperation plant in ethiopia heavy .Iron magnetic seperation plant in ethiopia,ethiopia iron magnetic seperation plant oct 04 2018 #183; magnetic separation and iron ore beneficiation magnetic separation is an old technique for the concentration of iron ores and for the removal of tramp iron since 1849 a number of patents on magnetic separation have been issued in usa and texts of .

The nonmagnetic gangue falls in a heap from the belt. Also, the reverse may be the case. The gangue may be the magnetic material in certain cases. Iron ores and manganese ores are the main ones for which we use magnetic separation. Magnetite and Chromitite ores (both iron ores) use this method on a large scale to remove their impurities.

Miningpedia is a valuable and professional communication platform who focuses on providing mineral processing knowledge, mineral extraction process and the concentration of ore.

Concentration Of Ore By Magnetic Separation. Sep 18 2012 material removed is quite small and dry separation is the general rule. Magnetite Iron ore beneficiation plant is also separators to remove the high concentration of Iron ore beneficiation plant iron ore processing plant for sale.

Magnetic iron ore separation process magnetic iron ore .Magnetic separation and iron ore beneficiation magnetic separation is an old technique for the concentration of iron ores and for the removal of tramp iron since 1849 a number of patents on magnetic separation have been issued in usa and texts of some of the patents before 1910 describe a

Magnetic Separation and Iron Ore Beneficiation Magnetic separation is an old technique for the concentration of iron ores and for the removal of tramp iron. Since 1849, a number of patents on magnetic separation have been issued in USA, and texts of some of the patents before 1910 describe a variety of magnetic separators for mineral processing.

CTB Series Permanent Magnetic Separator for Iron Ore Gold Ore Dressing Plant It is widely applied in the separation of various kinds of iron ores and gold ore. In order to increase the grade or capacity, several sets of wet drum magnetic separators can be installed in series connection or parallel connection. High Return Iron Ore Mining

Mar 01, 2020#0183;#32;Based on the characterization studies and selective flocculation/magnetic separation performed with an iron ore slimes sample, it was concluded that 75 % of the particles were below 10 m and the specific weight was g/cm 3. The main identified

WhatsApp)

WhatsApp)