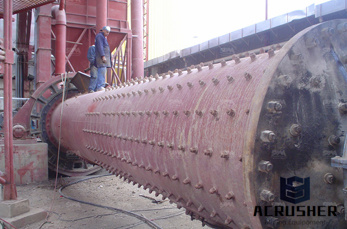

(PDF) Grinding in Ball Mills: Modeling and Process Control

The paper presents an overview of the current methodology and practice in modeling and control of the grinding process in industrial ball mills. metallurgy, cement production, chemical

WhatsApp)

WhatsApp)

The paper presents an overview of the current methodology and practice in modeling and control of the grinding process in industrial ball mills. metallurgy, cement production, chemical

Quality Control of Cement from sample crushing and fine grinding to elemental analysis. To produce highquality cement, the mineralogical and chemical composition of raw materials as well as intermediate and finished products has to be determined.

multivariable process control in clinker grinding. modern cement grinding process with close circut SBM. modern cement grinding process with close circut. Total: (10)

Our ECS Product Control Solution is the integrated OEM standard for most FLsupplied mining and cement equipment/products maximising the products'' ROI, while our ECS Machine Control Solution can control any thirdparty machinery in your operations. Both allow you to fully automate the equipment, ensuring you get the most from its functionality, while eliminating the risk of operator error and

Our Process Optimization Model Predictive Control (MPC) application can be applied to any process area in cement production. The application: Provides crushing or grinding optimization; Provides performance information to help reduce process

The Process Grinding Of The Cement. The Cement Manufacturing Process Advancing Mining. Cement manufacturing is a complex process that begins with mining and then grinding raw materials that include limestone and clay, to a fine powder, called raw meal, which is then heated to a sintering temperature as high as 1450 176C in a cement kiln.

LEADING TECHNOLOGY IN BALL MILL CONTROL. With MILLMASTER KIMA Process Control offers the most robust, open and easy to handle Advanced Control System in the Cement Industry. Since 1996 this AutoPilot system was installed in hundreds of cement

Click here to know more about the cement grinding process of Surya Gold Cement. Surya Gold Cement Manufacturing Cement Grinding Process Freshness Calculator + customercare

cement grinding process control : Cement Grinding Application, based on multivariable model predictive control (MPC) technology, has the flexibility to meet process and quality control requirements. In all cases, design of the control scheme is based on the specific process layout.

Aug 21, 2017#0183;#32;Grinding right up the wall or posts is probably the worst part about the grinding process in my opinion. You basically have 2 options. You can use a hand grinder and be on your hands and knees for hours or use a smaller walk behind grinder that has edging capabilities.

The grinding process consumes the most energy in the cement production, its energy consumption accounts for more than 70% of the total power consumption in the whole process of cement production. There are three main grinding processes in the cement production: raw meal grinding, cement grinding, and raw coal grinding.

The Vertical Roller Mill (VRM) reduces the power consumption for cement grinding approximately 3040% associated with other grinding mills. The process variables in cement grinding process using

PROCESS CONTROL FOR CEMENT GRINDING IN VERTICAL ROLLER MIL

The process technology of this cement grinding is still limited in China. In fact, the cement vertical grinding final grinding products can be compared with the ball mill, which can meet various engineering needs. The selection rate of the cement vertical grinding final grinding process has shown an increasing trend year by year.

The whole process of cement manufacturing in Messebo Cement plant which consists of two separate Cement Production lines can be summarized into the following processes ;as can be seen in the process and Quality flow diagram below; 1. Quarrying and Crushing 2. Raw material Storage and Transportation 3. Proportioning 4. Raw material Grinding

LEADING TECHNOLOGY IN BALL MILL CONTROL. With MillMaster KIMA Process Control offers the most robust, open and easy to handle Advanced Control System in the Cement Industry. Since 1996 this AutoPilot system was installed in hundreds of cement plants to operate mills fully autonomously. The rulebased expert system for Ball Mills, VRMs and also combined systems of Roller Presses and Ball

The separate grinding of cement is a grinding technology that saves electricity (reduced electricity consumption) and reduces carbon consumption (reduced carbon emissions). In addition, it

The show the flow diagram of the dry process of the manufacture of cement. 1. Dry Process. In the dry and semidry process the raw materials are crushed in a dry state. Then, they are processed in grinding mill

The Vertical Roller Mill (VRM) reduces the power consumption for cement grinding approximately 3040% associated with other grinding mills. The process variables in cement grinding process using VRM are strongly nonlinear and having large time delay characteristics also dynamics changes within 24 minutes.

HOLTEC has undertaken Performance Optimisation of the cement grinding circuits by doing process diagnostic studies in many cement plants. The paper describes the approach for the process diagnostic study for the optimisation of a ball mill circuit and is supported with typical case study done by HOLTEC in a mio t/a cement plant.

WhatsApp)

WhatsApp)