(PDF) SIZE REDUCTION BY CRUSHING METHODS

Mar 04, 2017#0183;#32;The objective of this lesson is to provide the details of size reduction methods involved in mineral processing using grinding methods and equipment. View fulltext Technical Report

WhatsApp)

WhatsApp)

Mar 04, 2017#0183;#32;The objective of this lesson is to provide the details of size reduction methods involved in mineral processing using grinding methods and equipment. View fulltext Technical Report

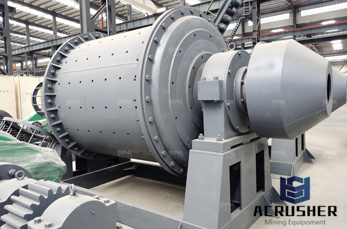

Size reduction equipment is equipment that crushes, shreds, compacts or in some way decreases the size of an object or material. Stone crushers are pulverizers that are used to compress or break apart very hard materials. These materials can include any kind of hard, solid, nonmetallic mineral.

#0183;#32;OBJECTIVES OF SIZE REDUCTION In the materials processing industry, size reduction or comminution is usually carried out in order to: Increase the surface area because, in most reactions involving solid particles, the rate of reactions is directly proportional to the area of contact with a second phase. Break a material into very small particles in order to separate the valuable amongst the two

Particle Size Reduction Equipment . Every day millions of people use products weve had a hand in producing without realizing it. MPE manufactures industrial size reduction equipment critical for the production of many food, chemical, and mineral (FCM) goods and products.

#0183;#32;size reduction,laws involved in size reduction,application amp; mills 1. SIZE REDUCTION Size reduction is the process of reducing the particle size of a substance to a finer state of subdivision to smaller pieces to coarse particles or to powder. Size reduction process is also referred to as comminution and grinding.

#0183;#32;Coal preparation plant process and equipment for coal washing. published date: . The necessity of coal preparation. Various mineral impurities are mixed in the raw coal mining process. The quality of raw coal is affected by technical equipment and geological conditions.

Our Size Reduction machines efficiently reduce the size of industrial material such as wood, coal, limestone, gypsum, aggregates, waste materials and much more to a specified size. Watch this video to learn more about our comprehensive selection of industrial crushing solutions.

Fines duty grinders treat coal with a top size of about 25 mm to yield a fine product with 75% passing 150 microns (100 mesh). Ultrafinesduty pulverizers are used for ultrafine grinding of coal with a top size of 1 mm to give a product 95% finer than 75 microns (200 mesh). Coarse and mediumduty breakers and crushers are used for primary size reduction purposes,, for size reduction of ROM or raw coal.

Production of Superclean Coal by WetGrinding and Selective . coal to 10 mesh, (2) use concentrating table to remove pyrite and other minerals, (3) wet grind coal to an ultrafine particle size to liberate coal from pyrite and of otherChlorine reduction from coal by wetgrinding was investigated using sample IBC1 09 ( ash, 1 .13% sulfur, and % chlorine).

Coal Centre Coal sampling and analysis standards 4 Abstract Each year, billions of tonnes of coal are traded in regional and international market for use in power generation, steel and cement making, and many other purposes. In commercial operations, the price of coal

Size reduction process is also termed as Comminution or Diminution or Pulverizations. There are many types of sizereduction equipment, Factors related to natu re of raw m aterials affecting

Handling a World of Materials. TerraSource Globals mission is to ensure the success of those that power, feed and build the world. To succeed, every member of our team is committed to upholding our position as the partner of choice for companies whose growth and profitability depend on innovative, durable and costeffective solutions for crushing, screening, feeding and processing raw

Learn More About Our Size Reduction Equipment. Contact us today to discuss your desired application in detail with one of our experienced sales engineers. We will work with you to analyze your unique needs and find the right size reduction equipment for your job. Call (314) or email us at info for more information.

Our size reduction equipment options include both top feed or horizontal front feed hogs. Both are of the same heavy duty rugged construction. Our rugged and selfcleaning Rotary Disc Screens can be used for the highspeed, consistent separation of oversized and undersized components. The new Chip Hog#174; is a revolutionary hammer mill with the heavy duty, high capacity features of a primary wood

WhatsApp)

WhatsApp)