Calcium carbonate production equipment YouTube

#0183;#32;Now chatting: Contact Us: production cycle for calcium carbonate processing line prod...

WhatsApp)

WhatsApp)

#0183;#32;Now chatting: Contact Us: production cycle for calcium carbonate processing line prod...

Calcium Carbonate Production Line Calcium Carbonate. Features of Oyster shell calcium carbonate powder production line Efficiency Under the same finished final size and the same motor power the capacity of Oyster shell calcium carbonate powder production line is twice as much as jet mill mixing grinder and ball mill and energy consumption decreased 30 safety and reliability As no rolling

Precipitated light calcium carbonate is a kind of calcium carbonate. The light calcium carbonate powder with fineness specifications of 125 mesh, 200 mesh, 225 mesh, 300 mesh, 600 mesh, 800 mesh, and 1250 mesh can be obtained through light calcium carbonate processing equipment.

Micro powder production line, providing a complete set of process and equipment for the production of ground calcium carbonate. Our products have been delivered to around the country, and gain a good reputation of product quality. The whole system has high automation, stable operation, and can achieve Longterm continuous operation.

The continuous precipitated calcium carbonate production equipment referred to in this invention provides for controlled form and size of calcium carbonate crystals, for 50 % reduction of power consumption in reaction cells, for universal application of the equipment as well as for its adaptability in view of lot production and simple increase of production capacities.

Calcium Carbonate Production Line,Calcium Carbonate As the leading manufacturer of calcium carbonate processing equipment in China, Pengfei has the largest production and export base of calcium carbonate production lines in the coastal areas. Chat Online

Precipitated calcium carbonate manufacturing process Posted: . Precipitated calcium carbonate/light calcium carbonate is a kind of calcium carbonate. Precipitated calcium carbonate powders with a fineness of 125 mesh, 200 mesh, 225 mesh, 300 mesh, 600 mesh, 800 mesh, and 1250 mesh are obtained through precipitated calcium carbonate processing equipment.

Calcium carbonate is a chemical compound with the formula Ca CO is a common substance found in rocks as the minerals calcite and aragonite (most notably as limestone, which is a type of sedimentary rock consisting mainly of calcite) and is the main component of pearls and the shells of marine organisms, snails, and carbonate is the active ingredient in agricultural lime and

Precipitated light calcium carbonate production . Precipitated light calcium carbonate is a kind of calcium carbonate. The light calcium carbonate powder with fineness specifications of 125 mesh, 200 mesh, 225 mesh, 300 mesh, 600 mesh, 800 mesh, and 1250 mesh can be obtained through light calcium carbonate processing equipment.

Calcium carbonate Micro powder production line material. Micro powder production line providing a complete set of process and equipment for the production of ground calcium carbonate Our products have been delivered to around the country and gain a good reputation of product quality The whole system has high automation stable operation and can achieve Longterm continuous operation

Heavy calcium carbonate is commonly used as filler in artificial floor tiles, rubber, plastics, The production of heavy calcium is divided into dry and wet processes. The heavy calcium dry ultrafine processing equipment is mainly composed of grinding and grading equipment.

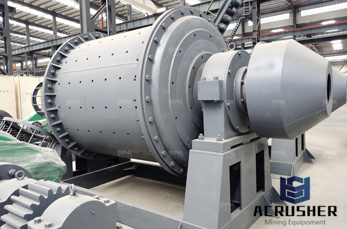

Calcium carbonate production line is to produce calcium carbonate powder by grinding basic material such as limestone or marble. And the calcium carbonate plant includes a complete set of calcium carbonate manufacturing equipment. For example, there are crusher, vibrating feeder, elevator bucket or belt conveyor, calcium carbonate grinding mill, air classifier, silos, dust collector, calcium

calcium carbonate production line italy. Top Calcium Carbonate Production Line Equipment. Calcium carbonate production line is to produce calcium carbonate powder by grinding basic material such as limestone or marble And the calcium carbonate plant includes a complete set of calcium carbonate manufacturing equipment For example, there are crusher, vibrating feeder, elevator

Equipment for GCC Production Process. A ground calcium carbonate production line consists of a complete set of equipment. As stated above in the manufacturing process of ground calcium carbonate powder, the process consists of crushing machine, grinding mill, classifier, dust collector, packing machine, transfer equipment such as conveyor or bucket elevator and optional coating machine.

Calcium carbonate are approved by the Foods and Drug Administration of USA, primarily for Calcium enrichment for chewing gum based and for cherry brining. Calcium carbonate is known as whiting in ceramics/ glazing applications, where it is used as a common ingredient for many glazes in

Now the commonly used calcium carbonate powder has a fineness of 325 to 2500 mesh size. Next, I mainly introduce what type grinding mill is used. Jaw crusher. The jaw crusher is one of the auxiliary equipment of the calcium carbonate powder production line. It is used to crush the raw materials size to the grinding conditions.

WhatsApp)

WhatsApp)