How can one select ball size in ball milling and how much

How can one select ball size in ball milling and how much material should be taken in mill com/blog/calculateandselectballmillball ball to material weight ratio, milling time,

WhatsApp)

WhatsApp)

How can one select ball size in ball milling and how much material should be taken in mill com/blog/calculateandselectballmillball ball to material weight ratio, milling time,

Retention time is the amount of time a compound spends on the column after it has been injected. If a sample containing several compounds, each compound in the sample will spend a different amount of time on the column according to its chemical composition each will have a different retention time.

#0183;#32;The residence time distribution (RTD) of mineral slurry and slurry holdup volume in an industrial ball mill has been successfully studies using tracer tests. Six different conditions of solids concentration and three levels of ball loading were assessed. The effects of the slurry solids concentration and the ball loading on the mean residence time of slurry were clearly depicted in the

Milling Time Calculator This will compute the time an end mill to take to remove material based on feedrate,area, depth, cutter diameter, and depth increment. This is used for pocket milling and face milling. Use the other calculators on this web site to calculate the feed rate. quot; /gt; Grinding Mills: Ball Mill amp; Rod Mill Design

To participate in the 911Metallurgist Forums, be sure to JOIN amp; LOGIN Use Add New Topic to ask a New Question/Discussion about Grinding. OR Select a Topic that Interests you. Use Add Reply = to Reply/Participate in a Topic/Discussion (most frequent). Using Add Reply allows you to Attach Images or PDF files and provide a more complete input. Use Add Comment = to comment on someone elses

MATERIAL RETENTION TIME IN A BALL MILL amp; VRM Page 1 of 1. Aug 11, 2010#183; Re: MATERIAL RETENTION TIME IN A BALL MILL amp; VRM. You could do that by measuring the material flowrate Q[tons/h] through the mill as well as the quantity M[tons] of material that accumulates within the mill. The retention time, also called residence time, is the ratio (M/Q

How To Find Ball Mill Retention Time In Case Of Iron Ore . How To Find Ball Mill Retention Time In Case Of Iron Ore Pdf. calculate wet ball mill time batch ball mill. calculate wet ball mill time batch ball mill latest wet ball mill plant of turmeric, wet ball mill machines sells, wet ball mills equation, wet ball mill media balls for brazil iron mine, wet ball mill balls ore mill suppliers

Retention time ball mill grinding mill chinaesidence time ball millaterial retention time in a ball mill amp vrm international ear all can anybody suggest me how to calculate the material retention time in a closed circuit ball 187 learn more the retention time of ball mill of cement production.

#0183;#32;Re: MATERIAL RETENTION TIME IN A BALL MILL amp; VRM You could do that by measuring the material flowrate Q [tons/h] through the mill as well as the quantity M [tons] of material that accumulates within the mill. The retention time, also called residence time, is the ratio (M/Q) [h].

How To Calculate Material Residence Time In A Vertical. calculate ball mill retention time sirptsciencecollegeorg ball mill, the roller mill consumes 40 to 50 % less energy By combining 3, The main influencing factor on the retention time is the mill length, the retention time of ball mill of cement production, Vertical Roller Mill in Cement Industry,Main Structure,

Material retention time in a ball MILL amp; VRM. Dear all can anybody suggest me how to calculate the material retention time in a closed circuit ball MILL in each compartment?The retention time, also called residence time, is the ratio (M/Q) [h] .

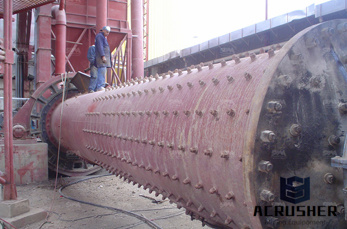

Ball Mills are generally used to grind material 1/4 inch and finer, down to the particle size of 20 to 75 microns. To achieve a reasonable efficiency with ball mills, they must be operated in a closed system, with oversize material continuously being recirculated back into the mill to be reduced.

The optimal retention time depends not only on the feed material and the desired comminution result but also on the ball charge filling ratio and particularly on the L/D ratio. On the basis of the present results and considerations, a specific optimisation of ball mills in semifinishgrinding plants can be done.

Ball mill what is the % of filling by balls and % of filling by materials ? ball mill size dia=2 meter, length 8 m, inner dia= m, material to be grinded= illuminate, ball size= 20,30,40 mm

The mill product can either be finished size ready for processing, or an intermediate size ready for final grinding in a rod mill, ball mill or pebble mill. AG/SAG mills can accomplish the same size reduction work as two or three stages of crushing and screening, a rod mill, and some or all of the work of a ball mill.

how calculate retantion time of cement ball . Inicio; how calculate retantion time of cement ball; Christmas special! Limited time offer, price concessions, up to 66%, come and consult!Inquiry. Clasificador Espiral . Como parte importante de la l#237;nea de beneficio, clasificadores

The basic parameters used in ball mill design (power calculations), rod mill or any tumbling mill sizing are; material to be ground, characteristics, Bond Work Index, bulk density, specific density, desired mill tonnage capacity DTPH, operating % solids or pulp density, feed size as F80 and maximum chunk size, product size as P80 and maximum and finally the type of circuit open/closed

OK mill and the retention time in the mill is shorter, the product will not be heated up as much as in a ball mill. This means that a lower degree of dehydration of the gypsum must be anticipated. This may not be a problem if the gypsum is sufficiently reactive to control the setting reactions, which is normally the case. If in special

(Ball mill classification system optimization through functional performance modeling, Nov. 17, McIvor et al., 2017, Mining Engineering) described circuit classification system efficiency (CSE), equal to the percentage of coarse (plus circuit P80 target size) material in the ball mill. It can be measured and then increased through

WhatsApp)

WhatsApp)