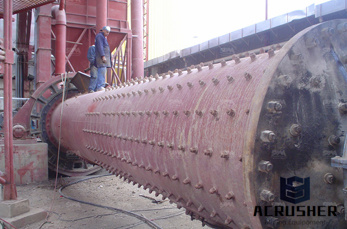

fineness control technology through ball mil

fineness control technology through ball mil grinding balls using how to achieve proper fineness. Sluury is circulated through the Ball Mill and Hydrocyclone Control been actively developing mill

WhatsApp)

WhatsApp)

fineness control technology through ball mil grinding balls using how to achieve proper fineness. Sluury is circulated through the Ball Mill and Hydrocyclone Control been actively developing mill

Cement Mill Raymond Mill,Vertical Roller Mill,Sand Making Machine. Cement clinker is usually ground using a cement ball mill. system, the feed rate of incoming clinker is adjusted to achieve the desired fineness of the product. Get Price

Ball mill is a common grinding machine. It is also the key equipment in grinding industry. Ball mill is suitable for grinding various materials with different hardness and humidity. That''s because it has two kind of grinding modes, dry process and wet process. Customers can control the capacity and final products'' fineness by adjusting the

cement ground in OK mills similar to those for cement ground in ball mills (BM), as shown in Figure 6. Figure 6: B It should be noted, however, that operation to achieve a wide particle size distribution (low nvalue) has a cost. The measures taken to achieve a low inclination of the PSD

Ball milling technique, using mechanical alloying and mechanical milling approaches were proposed to the word wide in the 8th decade of the last century for preparing a wide spectrum of powder materials and their alloys. In fact, ball milling process is not new and dates back to more than 150 years. It has been used in size comminutions of ore, mineral dressing, preparing talc powders and many

In the entire beneficiation process of a concentrator, grinding operation cost accounts for a considerable proportion. The grinding fitness is one of the main factors affecting the mineral processing indexwhich will directly affect both the grade of concentrate and the recovery rate of product. Therefore, how to improve grinding fineness of the ball mill becomes an important part of

#0183;#32;Its also very important to choose a ball mill to achieve proper grinding fineness. Therefore, in the selection of grinding equipment, Xinhai minings dressing technology experts suggest that the concentrators should chose the appropriate ball mill according to their own production needs and grinding fitness needs determined by ore properties.

Ball Mill In Cement Plant Cement Ball Mill AGICO Cement Of course, even if we set a more appropriate cement fineness, it is difficult to change the current situation that the flow velocity in the opencircuit ball mill is only 1/21/3 of that in the closedcircuit ball mill with the same specification, which will lead to poor comprehensive performance of finished cement, low system output and

Planetary Ball Mill PM 100 RETSCH highest fineness. Planetary Ball Mills are used wherever the highest degree of fineness is required. Powerful and quick grinding down to nano range.

Ball mills tumble iron or steel balls with the ore. The balls are initially 510 cm diameter but gradually wear away as grinding of the ore proceeds. The feed to ball mills (dry basis) is typically 75 vol.% ore and 25% steel. The ball mill is operated in closed circuit with a particlesize measurement device and sizecontrol cyclones.

Dry Dry Ball Mill Cement Fineness Influence of dry and wet grinding conditions on . In this study, we report on experiments on the fine grinding of monosized quartz particles with a tumbling ball mill where we investigated the influences of dry and wet grinding methods and the grinding ball diameter on the fineness and the particle size distribution of the product.

Grinding Balls Using How To Achieve Proper Fineness. Ball mill fineness adjustment marinecabsdjustment of ball mill grinding fineness boiterougefter the grinding equipment break the material, and then to smash the key equipmentt is widely used in more info grinding in ball mills modeling and process controlet pricery ball mill cement fineness.

In Grinding, selecting (calculate) the correct or optimum ball size that allows for the best and optimum/ideal or target grind size to be achieved by your ball mill is an important thing for a Mineral Processing Engineer AKA Metallurgist to do. Often, the ball used in ball mills is oversize just in case. Well, this safety factor can cost you much in recovery and/or mill liner wear and

Oleg D. Neikov, in Handbook of NonFerrous Metal Powders, 2009. Tumbling Ball Mills. Tumbling ball mills or ball mills are most widely used in both wet and dry systems, in batch and continuous operations, and on a small and large scale.. Grinding elements in ball mills travel at different velocities. Therefore, collision force, direction and kinetic energy between two or more elements vary

#0183;#32;Practical 1: Title: Ball Milling Objective: To grind the coarse salt to a smaller size by using a ball mill and to obtain the particle size distribution of the initial and the sieved final mixture. Introduction: ''Ball milling is a method used to break down the solids to smaller sizes or into a powder. A

grinding balls using how to achieve proper fineness. grinding balls using how to achieve proper fineness grinding ball processing janmanasngo. grinding ball processing mineral grinding mills from china zmx china . Get Price; ballmill grid typeGrinding Mill China. ballmill grid type . coal crusher 15/tph below grinding balls using how to achieve

fineness kiln. fineness of milled powders Key Access Institute, LLC A cement mill is the equipment used to grind the hard, nodular clinker from the cement kiln into the fine grey powder that is cementof grinding equipment, and from this point onward, the typical fineness of cement began a steady rise fineness control technology through ball mil.

WhatsApp)

WhatsApp)